SRK completed several studies on gold-bearing, complex-sulfide ore feed and autoclave tailings from a mine on the Carlin trend in northern Nevada. Feed, mill and autoclave products were studied at different stages of an autoclave process to identify the reason for variable recovery in some ores.

Under the standard operating conditions of the autoclave mill, there is a high recovery of gold, which occurs predominately as chemically included gold within arsenian (arsenic-containing) pyrite. This pyrite is exposed through crushing and oxidises almost completely within the autoclave. Typically, recoveries above 90% are observed.

Where recovery is poor, two mineralogical forms were identified via microscopic analysis that may have prevented complete oxidation of the arsenian pyrite and/or leaching of the gold:

- Arsenian pyrite occurs as fine inclusions (<40 μm in size) within quartz and illite; even with fine grinding, these inclusions also appear in the autoclave residue. Such pyrite is still present in mineralogical sections of the residue reflecting the lack of exposure to leaching solution and protection from thermal decay and thus does not get oxidised.

- Trace amounts of gold with a mixture of illite/smectite clay, montmorillonite and free carbon were observed by Laser Ablation Inductively Coupled Plasma Mass Spectrometry, indicating potential for preg-robbing by clays and carbon. Preg-robbing is a process that prevents some of the gold from being recovered, making extraction less effective.

To investigate these concerns, metallurgical testwork was completed and the following options identified to overcome the loss of gold:

- Finer grinding would release the gold-bearing pyrite

- Adding an oxidant, such as MnO, may pacify carbon, thus inhibiting potential preg-robbing; or

- Using a surface suppressant to depress the capacity for surface cation exchange on clays and carbon in the carbon leach step to pacify ‘preg-robbing’ phases

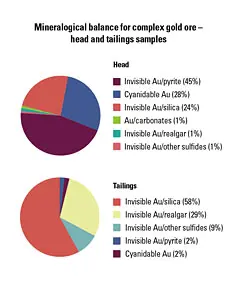

A better understanding of ore and tailings mineralogical balance (as illustrated in the circle graph above) can provide valuable information for process engineering. Mineralogy may guide flowsheet development, troubleshooting and process optimisation efforts in operating mines. A critical aspect in the success of this work was the strong links with university research that SRK has developed and our ability to access such micro analytical methods of investigation.

SRK has completed similar studies on complex gold ores and gold occurrence in tailings for projects at other sites in Nevada, and also in Montana, Mexico, Peru, Brazil, South Africa, Mali, Zimbabwe, Tanzania, Russia, Armenia, Malaysia, Greenland, Serbia, Spain and Turkey.

Bowell RJ, Gingrich M, Bauman M, Tretbar D, Perkins W, and Fisher P, 1999: “Occurrence of gold in the Getchell ores”, Journal of Geochemical Exploration, v.67, 127-143.

Bowell RJ, Perkins WF, Tahija D, Ackerman J, Mansanti J, 2005: “Application of LAICPMS to trouble shooting mineral processing problems at the Getchell mine, Nevada”, Minerals Engineering, v.18, 754-761.